This beer is the first brew to go into my 15 gallon Dad’s Hat rye whiskey barrel. That barrel is destined for sour solera duty, but first I want to brew a couple of big clean beers to make the most of the barrel’s fresh whiskey character.

This stout is based on a KBS clone recipe from Zymurgy that I first brewed way back in 2013. That was a great beer, and I’m excited to try making it again.

This beer is a collaborative project with my friend Adam. We brewed this on his 20 gallon Ss Brewtech system, which was fantastically convenient. I would’ve needed 3 brew days to produce enough volume for the barrel on my system.

Also convenient, I had someone to split the 15 gallons of finished stout with. That’s a lot of strong beer!

Recipe

If you’re an AHA member you can read the original recipe here. Or if you aren’t, it’s been republished pretty widely. A quick Google should turn it up.

We’re deviating from the recipe a bit. We’re leaving out the chocolate and coffee this time, and we also pulled the OG back a bit from 1.094 to 1.084. I was feeling a bit gun shy.

Originally I was thinking of spinning 5 gallons off into its own chocolate/coffee variant, but in the end decided to just keep it all straight.

Batch size: 16.5 gallons

Target OG: 1.084

Target FG: 1.020

Calculated IBU: 60

Grain bill (pounds):

39.75 US 2-row (76.8%)

4.5 Flaked Oats (8.7%)

2.25 Chocolate Malt (4.4%)

2.25 Roasted Barley (4.4%)

1.5 Crystal 120 (2.9%)

1.5 Blackprinz (2.9%)

Water:

Baltimore County MD tap water + a campden tablet to remove chlorine

Mash:

155 °F @ ~1 qts/lb (limited by mash tun size)

Then sparge to total pre-boil volume of 18.9 gallons

Hops:

3 oz Nugget @ 60 minutes

3.75 oz Wilamette @ 25 minutes

5.25 oz Wilamette @ 10 minutes

Yeast:

About a trillion cells of WLP001 from two large starters.

Fermentation temp 65 °F

Notes

2019-11-05 - The barrel arrived via fedex. This was much earlier than ideal, but I was anxious that they might go out of stock while the beer was fermenting. Patience is often the hardest part of making beer. Next time, have beer ready, then get the barrel.

To keep the barrel fresh and leak free, I added most of a handle of Evan Williams bourbon. I rolled it around gently a couple times per day and left it standing on each end so the heads could say as wet as possible.

2019-11-10 - Brew day! Things went pretty smoothly. Mash temps were a bit all over the place. I probably shouldn’t have picked this batch to try running Adam’s system for the first time.

Ended up with about 16 gallons of 1.082 wort. Put about 12 gallons into a 14 gallon Ss Brewtch unitank, and the other 4 went into a hpde bucket in my old faithful fermentation fridge. Fermented at 65 °F.

2019-12-01 - Barrel day. I dumped out the whiskey that had been soaking in the barrel. Of the ~1.3L I put in, about half was either absorbed or lost to evaporation.

Transferred the beer into the barrel. FG 1.026. Abv was a little lower than intended. I think we can count on a barrel this wet increasing the alcohol significantly though. I’d estimate the final ABV is ~10.5%

2020-01-04 - Packaging day. Adam had been tasting the beer about once a week to see how it was coming along.

We both did a final taste on bottling day. The oak was starting to taste pretty strong to me, but Adam thought it was still mild. The booziness of the bourbon was definitely there. Probably could’ve left it for longer, but we decided it was a good compromise to bottle now.

We bottled 10 gallons in 12oz bottles, primed to ~2.2 vols CO2. Adam kegged the last five gallons.

In the end I got a stack of 3 cases of barrel aged stout. I hope it tastes good and ages well, there’s sure a lot of it!

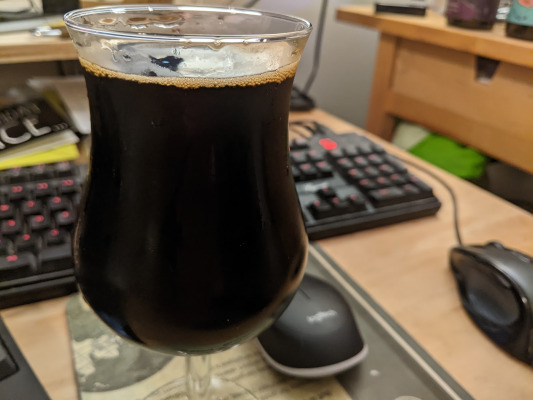

2020-02-06 - Tasting the first bottle.

The beer pours with a large tan head. There is more carbonation than I was intending.

I’ve never been one to describe smell and taste very well, but the aroma is nice. It has some pleasant vanilla/oak notes.

It’s good in the flavor department too. Smooth, roasty, bourbon-ey. The excess carbonation is making the mouthfeel a bit thin, but once it sits and calms down a bit it’s a nice sipper.

It’s a shame the carbonation is a bit off. I’ll just let these sit a bit after I pour them, to come down to a better carb level. Otherwise I’m happy with this batch, and looking forward to seeing how it changes with age.

2020-05-11 Man this is carbonated. Starting to suspect infection, though the flavor/aroma are still good. Degassed a sample from one of the bottles and took a gravity reading: 1.017. I’ll measure again in a couple months and see if its stable.

2020-06-05 Still 1.017. This bottle was less carbonated too.

2020-11-10 One year since brew day. Oof, it’s been a hell of a year since we brewed this beer. But lets focus on the tasty beverage…

I’ve had a bunch of these since June. Some are highly carbonated, some nice and low. No bottle bombs. At this point I don’t suspect an infection. I think I must have just had an uneven distribution of priming sugar at bottling time.

Opened a bottle today to celebrate the one year mark. This one has a moderate carbonation level. The flavor is still great: roast grains, chocolate, oak, whiskey. I don’t detect any off flavors from the age. No oxidization issues yet. I’m looking forward to enjoying more this winter.

Changes for next time

I’d go a little higher ABV next time and also risk leaving the beer in the barrel a little longer.

Also much less carbonation. I’m not sure if we screwed up the priming sugar or if this really is what 2.2 vols of CO2 looks like. It’s been ages since I bottled anything before this batch. We’ll try going lower for the old ale that’s going in this barrel next.